Warehouse

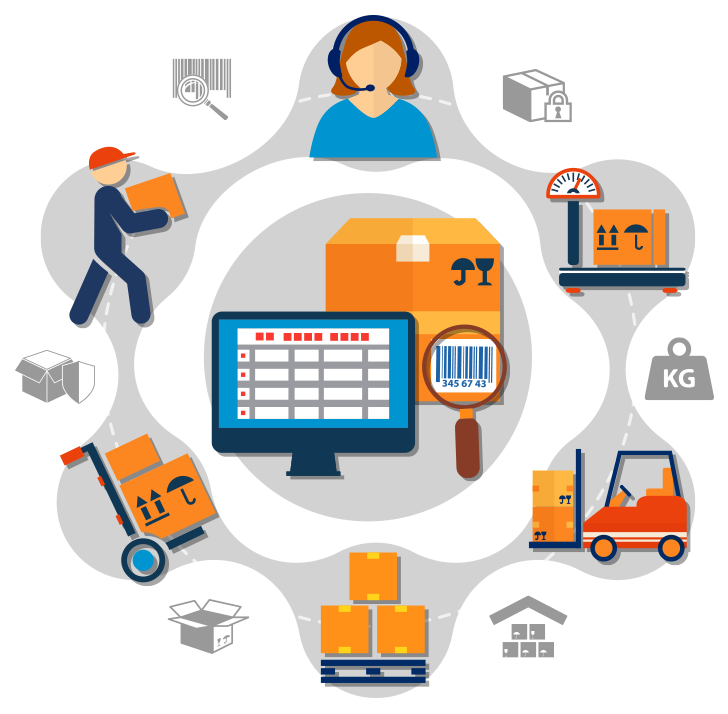

INVENTORY MANAGEMENT

Business intelligence helps businesses to refine assorted inventory and optimize supply quantities and inventory allocation across stores, by analyzing detailed historical data such as buying patterns and the demographics of customers. This helps in minimizing the risk of out-of-stock situations by analysing safety stock data as well as inventory and sales information to create accurate forecasts — business intelligence provides the valuable data that a forecasting tool for small business needs.

Predicting over-stock situations before they become a major problem by drawing on replenishment, sales, and forecasting data. Reducing in the long-term the number of inventory items with a slow turnover, by measuring demand and sale levels on a per-location and per-season basis, while taking into account the impact of price changes are the features Info Science focuses on.

Using physical inventory counts to generate inventory verification schedules and thus maintaining highly accurate inventory data that can be used to inform the ordering process. Analysing and monitoring inventory levels for both finished goods and the materials used in producing the finished goods and also to better understand buyer behavior, in order to improve the cost-effectiveness of the inventory control process.

We help in determining the most time-effective and cost-effective way to get rid of slow-selling inventory by identifying the discounts that have had the most significant impact in the past as well as the locations where specific products have sold the most.